Technical Support

Q&A

Maxflex has over 60 commercial specifications. Based on biomechanical design, the sheet products cover different polymer materials, formulations, dental sheet structures, sheet thicknesses, and diameter sizes. For the automated production line of aligners, there are different widths of rolls of customers choice. In addition, Maxflex also provides sheet products covered with protective film to prevent mold contamination during the vacuum molding process and improve the clarity of the clear aligner.

Maxflex dental sheet products can be used for making attachment template, clear aligner, retainer, night-guard aligner, aesthetic aligner, oral healthcare products, etc.

Maxflex focuses on innovation and has the ability to design, develop, and customize dental sheets. Customization can be done according to different stages of orthodontic treatment and biomechanical needs of customers, meeting their differentiated needs.

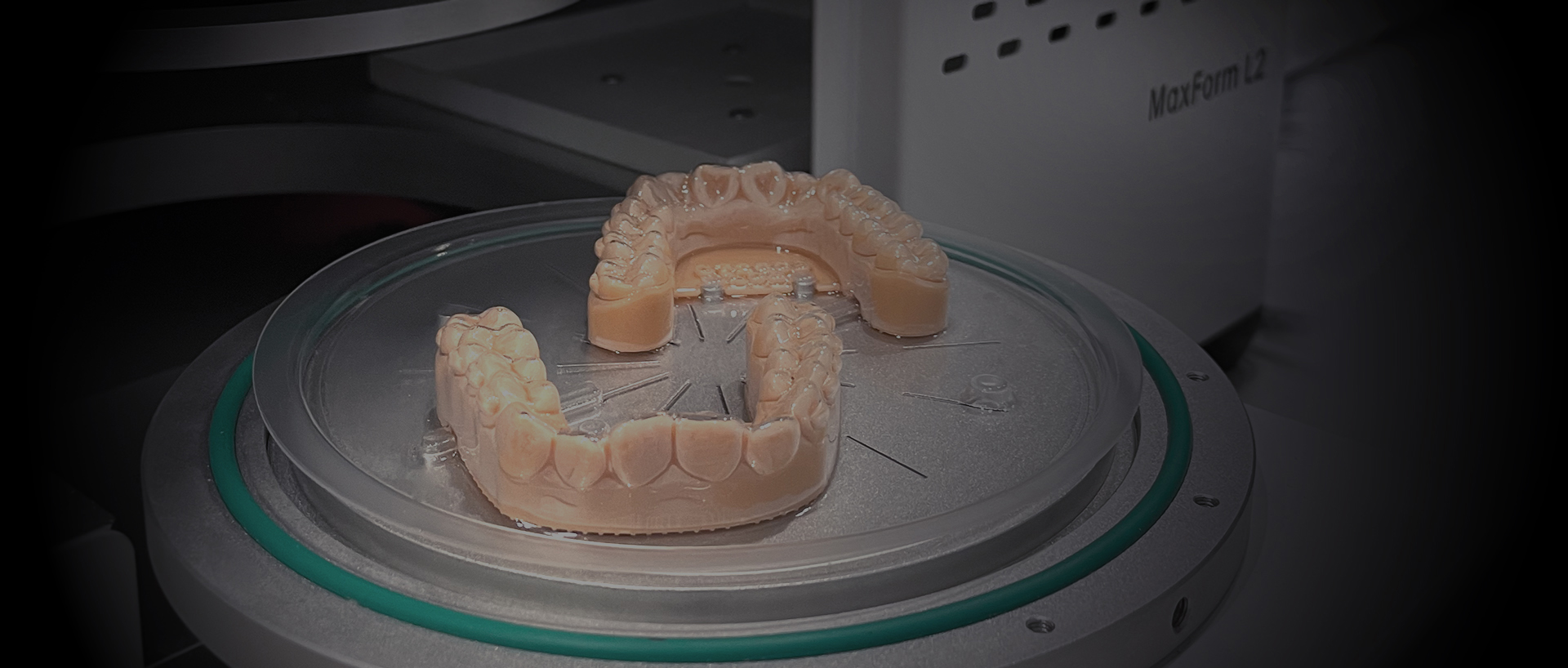

Maxflex dental sheet products mainly include circular discs with diameters of Φ120 mm and Φ125 mm designed according to traditional pressure thermoforming equipment. The specially designed Maxform L2 dual-Aligner pressure thermoforming machine with a diameter of Φ133mm circular disc doubles the production efficiency of dental aligners. For more information of equipment products, please visit our website www.maxflexbrace.com

For customers who have the need to punch sheets from rolls prior to thermoforming, Maxflex provides independently developed punching machine that is equipped with punching and cutting function for making circular sheets with diameters of Φ120 mm, Φ125 mm, or Φ133 mm, respectively, w/o protective film.

According to the width design of conventional automatic aligner manufacture lines, the width of roll are set to 102 mm and 137 mm, respectively. Roll length depends on roll thickness and customer requirements. The weight is usually 15-20 kg/roll.

Maxflex dental sheets and rolls design is usually one side matte and one side smooth, with the aim of preventing adhesion that may occur during stacking, transportation, and storage of sheets or rolls. When the sheet is heated and molded into aligner, the mist surface will disappear under heat and pressure, without affecting the clarity of the braces/aligner.

Maxflex also provides protective film covering product surface to meet the customer's needs for avoiding mold contamination and enhance the clarity of aligners. In addition, Maxflex can also provide professional tools for removing protective films and dental molds, so as to improve customer production efficiency.

Shanghai Maxflex Medical Technology Co., Ltd. was established in 2021 at No. 1169 Yuanqu Road, Anting Town, Jiading District, Shanghai, China. The factory covers an area of over 10,000 square meters and has the qualification to produce and sell Class II medical devices in China.

The company focuses on providing comprehensive solutions for clear aligner, offering a series of services including covering clear aligner sheets, processing device, software, accessories, process optimization and dental OEM services. Maxflex has more than hundred products varieties, which can meet the diverse needs of global customers.

The company has multiple professional production lines with an annual production capacity of over 100,000,000 pieces (1,500,000 square meters), aiming to become the world's leading and to provide one-stop clear aligner solution.

Shanghai Maxflex Medical Technology Co., Ltd. has a sound GMP, ISO 13485 system, class II medical device registration certificate in China and CE certificate. Maxflex has a complete set of dental sheets testing equipment that meets industry standards, and has independently developed patented dental sheets processing equipment and testing instruments, aiming to establish a new benchmark for material mechanics and biomechanics in the clear aligner industry.