Technical Support

Q&A

After using aligner trimming machine, the trimming area of the aligner may be relatively sharp. Tools such as polishing wheels can be used for manual operation, or a polishing machine can be used to polish the aligner edges.

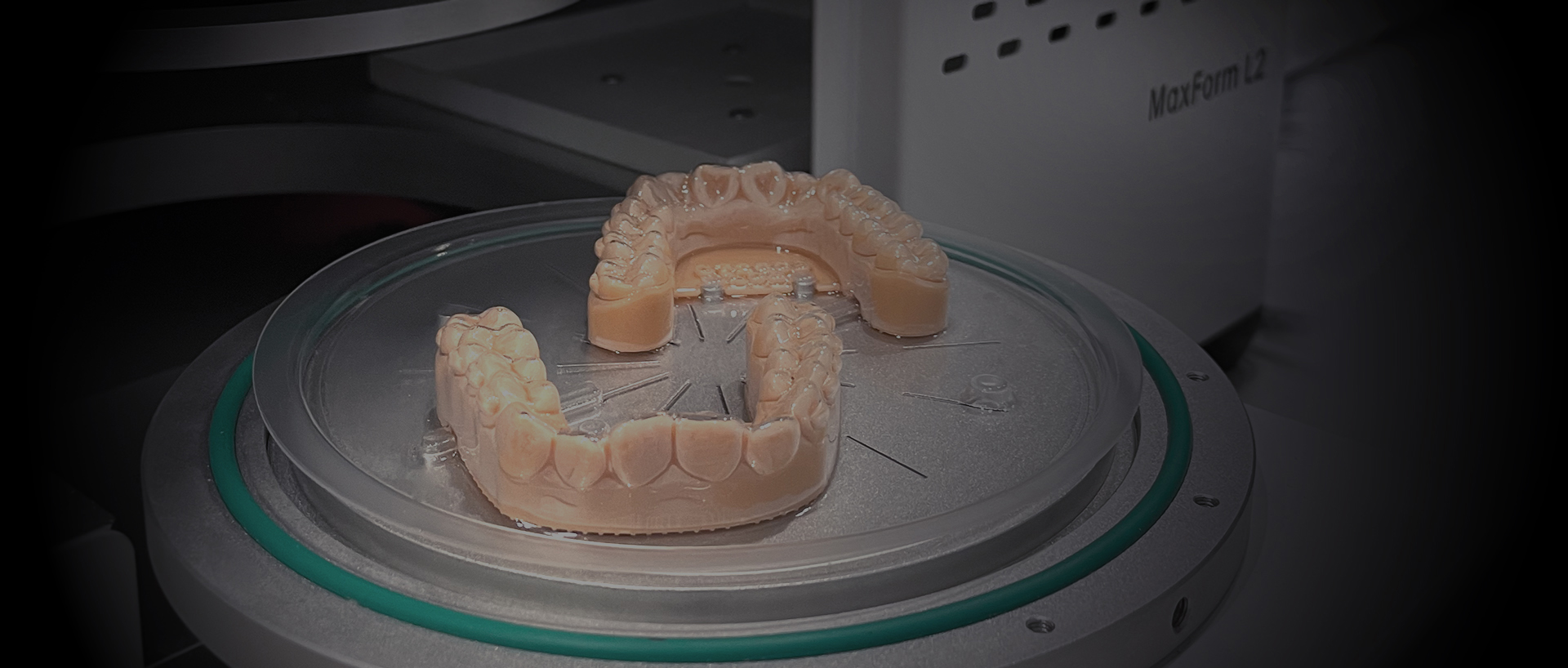

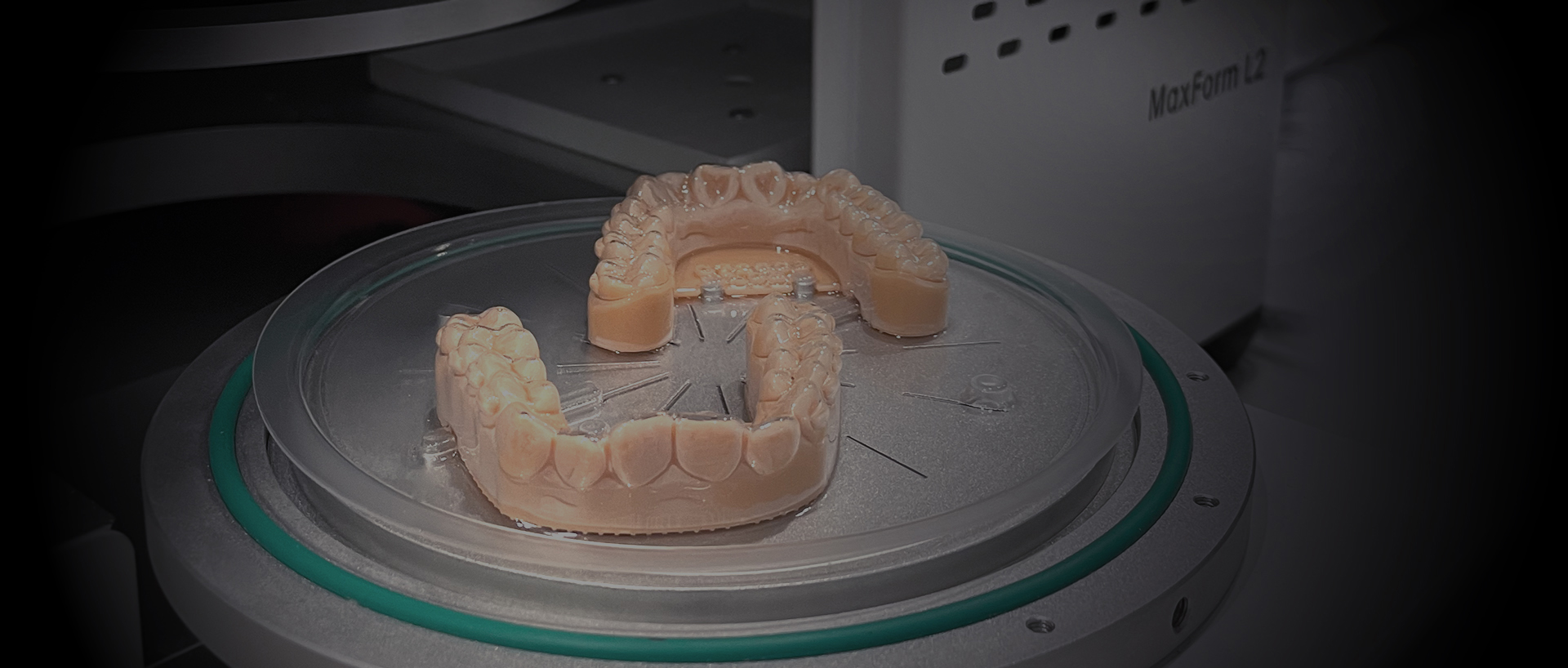

After thermoforming and trimming, Maxflex special prying tool can be used for demolding. The front end of the prying tool is thin and round, making it easy to remove the resin model.

For complex and difficult to demold aligners, oil-based or emulsified demoulding agents can be chosen to reduce the surface energy of the braces hence improve demoulding efficiency.

Maxflex technical service team provides professional guidance for routine equipment maintenance, while paid on-site maintenance services can be provided for complex maintenance needs. For relevant inquiries, please send an email to support@maxflexbrace.com

Maxflex technical service team also provides remote technical support, and all equipment are designed with a modular concept to minimize maintenance difficulties. Replacement of parts and calibration to restore for use is user-friendly, efficient, and with low maintenance cost. For relevant inquiries, please send an email to support@maxflexbrace.com

Maxflex equipment complies with local voltage standards, and customers around the world can plug in for immediate use after receiving the equipment.