Technical Support

Q&A

Q: Regarding one-stop solution, in order for Maxflex to produce finished aligners for us, all you need is oral scan data from us?

A: Currently, Maxflex has the capability to manufacture corresponding retainers based on oral scan data. For more information, please refer to our sales people.

After thermoforming, observe the imprints at the junction of teeth and gums. If the imprints are clear and distinguishable, the thermoforming effect is acceptable. If the imprint is unclear or even absent, the braces may not fit well.

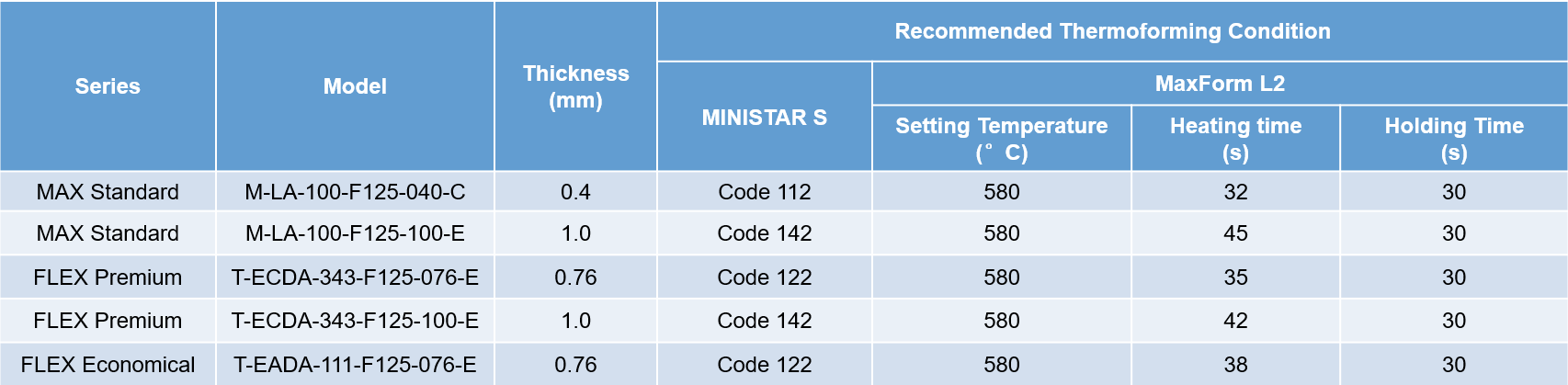

The requirements for dual teeth model thermoforming are: the width of the model arch≤ 68mm, and the height t ≤ 20mm; anterior inclination angle ≤ 45 degrees (angle with vertical Z-axis).

Dental sheet or roll products when exposed to air will absorb moisture. When thermoformed into aligner at high temperatures, the braces/aligner are prone to blistering. High temperature and humidity may exacerbate the risk of bubbles.

The speed of moisture absorption varies from dental sheets made materials, and different materials have different absorption capacity. For TPU type dental sheets, it is recommended to use them all within 15 minutes after opening, and for copolyester sheets, it is recommended to use them all within 8 hours after opening. For rolls, it is recommended to use them continuously as soon as possible after opening.